01732 496 523

Summary

The London Power Tunnels

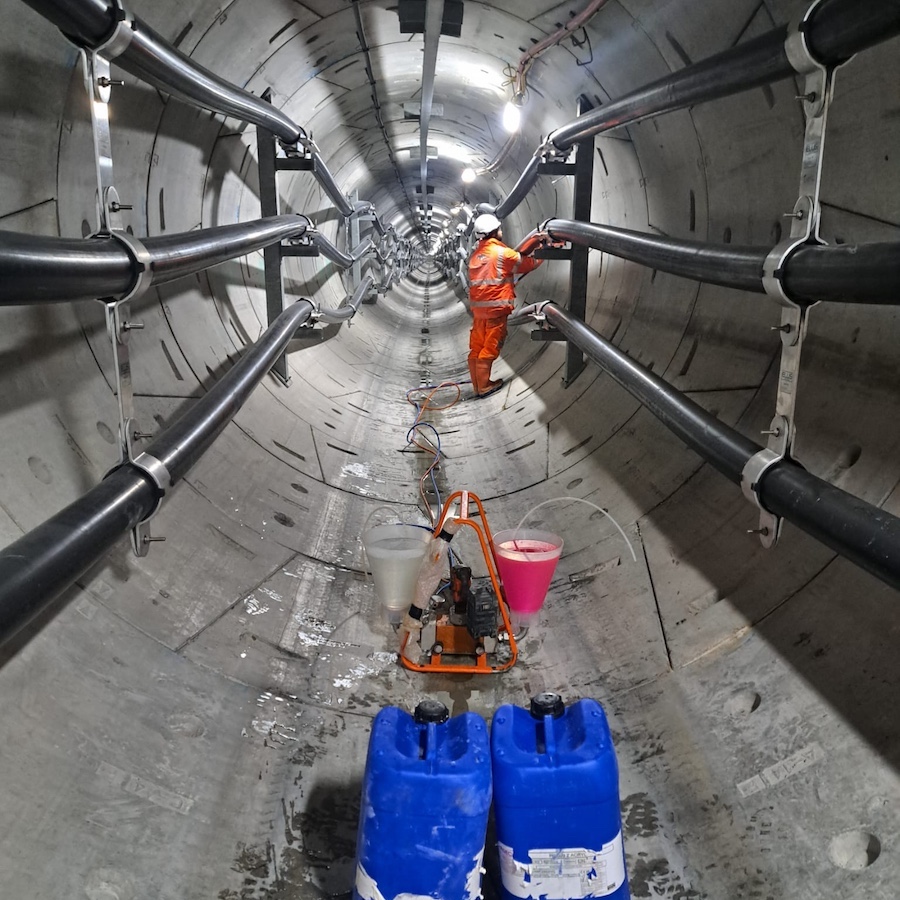

Starting in spring 2020, the London Power Tunnels is an immense seven-year and £1 billion project by the National Grid to rewire South London via deep underground tunnels. Resin injection tunnel waterproofing methods are set to be used throughout the project.

Most of the electricity supply in South London is currently transmitted through underground cables, traditionally found just below the road surface. However, work to maintain them is carried out at street level and can be disruptive.

By housing new, high-voltage cables in deep underground tunnels, the benefits include:

- Less disruption during construction as the majority of works will take place deep underground

- Future repairs and maintenance work can be carried out without disrupting traffic, residents and businesses

- Additional cables can be installed in the tunnels to meet future demand

The new tunnels will upgrade the network’s capability to ensure it is ready for London’s future energy needs. Resin injection tunnel waterproofing helps to fulfil the requirements on site.

The Project

Designed by engineers AECOM the 32.5km of 3m diameter tunnels are being constructed deep below the roads, rivers, canals, and tube lines between Wimbledon and Crayford.

At a depth varying between 10m and 63m below street level, the tunnel also required the construction of multiple vertical access shafts along the route. These ranged from 9m to 15m in diameter and up to 55m deep, allowing the specialist team from ASF Waterproofing to safely access the tunnels and carry out the resin injection waterproofing.

The tunnels are constructed using a tunnel boring machine (TBM) that places precast and interlocking concrete segments against the tunnel walls. The segments are fitted with a rubber gasket to seal the joints, however this is sometimes dislodged,

damaged or not seated properly, resulting in seepage of ground water under considerable hydrostatic pressure.

ASF Waterproofing Specialists were appointed by the Hochtief Murphy Joint Venture to undertake resin injection of these joints to seal them against water ingress.

The Solution

As experts in below-ground injection resin waterproofing, ASF Waterproofing were able to bring their considerable experience to bear on this project too. Utilising a variety of products, such as our exclusive range of advanced acrylic injection resins from TRADECC, ASF were able to waterproof the joints, providing a Type B solution in line with Section 11 of British Standard 8102:2022 for waterproofing.

The Result

ASF Waterproofing were engaged in Phase 2 of the London Power Tunnels project for 3 years, ensuring that all joints in the tunnel and access shafts were fully sealed against water.

"ASF have been engaged in the London Power Tunnels project by the Hochtief Murphy Joint Venture for almost 3 years, providing leak Injection, waterproofing, labour supply, and specialist material supply. They have consistently delivered their services to a high standard, always reacting well to short timeframes and always willing to help out wherever they can. I can recommend ASF for any project, they always give their all to find the most suitable solutions."

Chris Ashton, LPT2

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.