01732 360 095

In the realm of structural waterproofing, cavity drain membrane systems have emerged as a cornerstone of modern, robust waterproofing solutions.

For architects, specifiers, and contractors working on below-ground structures, understanding the intricacies of these systems is crucial for ensuring long-lasting, effective protection of the below ground properties and their contents.

This guide delves into the world of cavity drain membrane systems in greater detail, highlighting the benefits of the safest method of removing water. This includes the minimal preparation and disturbance required to existing substrates, the inclusion of a well-designed drainage system, and the use of a robust sump pump system for removing any captured water.

Leveraging Newton’s Expertise in Type C Waterproofing Systems

As the oldest and largest independent designers and suppliers of guaranteed basement waterproofing systems in the UK, Newton Waterproofing brings over 170 years of expertise to the table.

The Newton CDM, cavity drain membrane system, also known as Type C waterproofing, represents the pinnacle of contemporary waterproofing technology. This guide will explore the components, installation, and compliance requirements, including the crucial components of a cavity drain waterproofing system, providing you with the knowledge needed to confidently incorporate them into your waterproofing projects.

Type C systems are installed to the internal side of the below-ground structure, which should also utilise other types of protection to provide primary resistance against water penetration, ensuring that the cavity drain system is not overworked and collecting too much water.

What are Cavity Drain Membrane Systems?

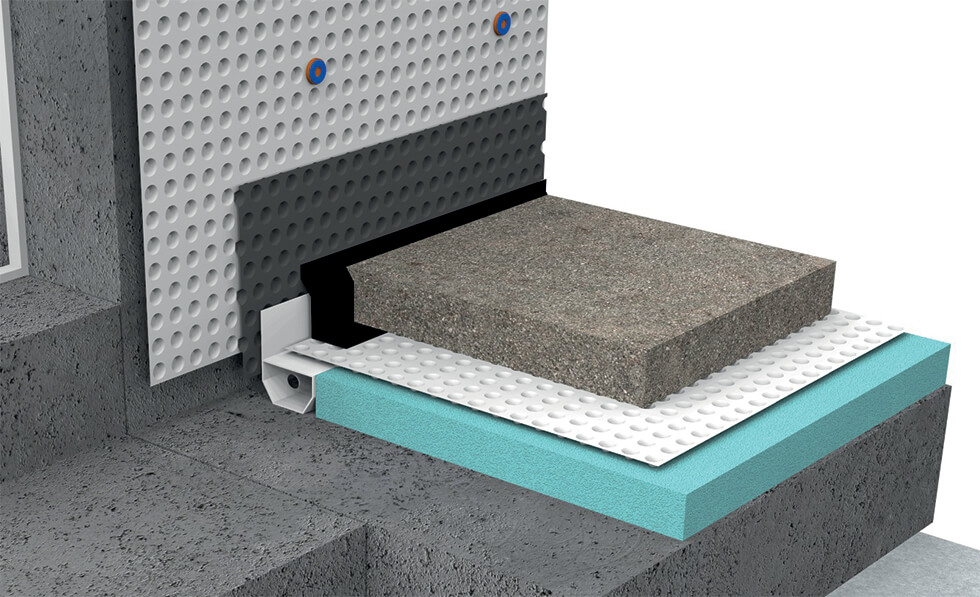

Cavity drain membrane systems, classified as Type C waterproofing under BS 8102:2022, are designed to manage and control water ingress in below-ground structures. Unlike other waterproofing methods that aim to resist water pressure, cavity drain systems collect water entering the structure before safely removing it.

The system consists of several key components:

- Cavity drain membranes: High-density polyethylene (HDPE) sheets with a studded profile that creates space between the membrane and the substrate to depressurise and divert ingressing water.

- Drainage channels: Installed at the base of the wall membrane and above weak points in the concrete to collect and direct water to suitable collection points.

- Sump pump system: Comprising a sump chamber and pump(s) to actively remove collected water from the structure where removal by gravity is not possible.

- Battery Backup: Secondary power supply provided by inversion of DC battery power to clean and efficient 230VAC power, to ensure continued pumping during power outages.

- Monitoring & Notification: Sophisticated, cloud-based monitoring of the pumping system that provides warnings of alarm events and pump health.

- Fixing and Sealing Ancillaries: Including fixing plugs, sealing tapes, and penetration sealing details to ensure a complete and robust installation.

The Newton CDM System: A Closer Look

Newton Waterproofing’s cavity drain membrane system, known as the Newton CDM System, offers a comprehensive solution for below-ground waterproofing. Our system includes a range of BBA approved membranes, each designed for specific applications, and all of which can also provide radon protection as required by the BR 211 guidance on protective measures for new buildings:

- 508 wall and floor membranes: A high-quality cavity drain membrane, supplied in various sizes.

- 508 eco Floor membrane: Designed with more studs per square metre to deliver higher compressive resistance as a component of floor installations. 100% recycled.

- 508R membrane and gas barrier: Heavier and stronger than standard membranes, and certified for use as a barrier to ground gases and hydrocarbons

- 520 eco Floor: A high drainage capacity floor membrane, generally specified where it is anticipated that there may be a risk of severe water penetration. 100% recycled.

As part of the CDM System, these membranes are specified in conjunction with the CDM BaseDrain drainage channels and Titan-Pro sump pump systems to provide a complete and maintainable waterproofing solution.

The Importance of Specialist Installation for Cavity Drain Membrane Systems

When it comes to implementing cavity drain membrane systems, the expertise of the installer is just as crucial as the quality of the products used. Employing a specialist, trained, and qualified installer offers numerous benefits and is essential for ensuring the longevity and effectiveness of your waterproofing solution.

Why Choose a Specialist Installer?

- Expertise and Experience: Specialist installers have in-depth knowledge of cavity drain membrane systems and extensive experience in handling various installation challenges. They understand the nuances of different substrates, environmental conditions, and potential complications that may arise during installation.

- Proper System Design: Qualified installers can assess your specific project requirements and design a tailored waterproofing solution. They consider factors such as hydrostatic pressure, soil conditions, and building structure to create an optimal system design.

- Quality Assurance: Trained installers follow strict quality control procedures, ensuring that every component of the system is installed correctly and to the highest standards. This attention to detail is crucial for the system’s long-term performance.

- Compliance with Standards: Specialist installers are well-versed in relevant building codes and industry standards. They ensure that the installation complies with BS 8102:2022, Building Regulations, and other applicable guidelines.

- Efficient Problem-Solving: Should unexpected issues arise during installation, experienced installers can quickly identify and resolve problems, minimising delays and potential long-term issues.

- Warranty and Guarantees: Many specialist installers offer guarantees on their work, providing you with additional peace of mind and protection for your investment.

Newton’s Network of Specialist Basement Contractors (NSBCs)

At Newton Waterproofing, we recognise the critical role that expert installation plays in the success of our cavity drain membrane systems. That’s why we’ve established a nationwide network of Newton Specialist Basement Contractors (NSBCs).

Our NSBCs are:

- Thoroughly trained in the design and installation of Newton waterproofing systems

- Regularly assessed to ensure they maintain high standards of workmanship

- Capable of providing meaningful, insured installation guarantees

- Supported by Newton’s technical team for complex projects

By choosing an NSBC for your cavity drain membrane installation, you’re not just getting an installer – you’re gaining a waterproofing partner with the backing of Newton’s 170+ years of industry experience.

The use of a specialist installer is not just a recommendation; it’s a crucial step in ensuring the success of your waterproofing project. Their expertise, combined with Newton’s high-quality products, creates a formidable defence against water ingress in below-ground structures.

Compliance with Building Codes and Standards

Cavity drain membrane systems must comply with several key standards and regulations:

- BS 8102:2022: The British Standard for protection of below-ground structures against water ingress.

- Building Regulations Approved Document C: Addressing site preparation and resistance to contaminants and moisture.

- NHBC Standards: Particularly Chapter 5.4 for waterproofing of basements and other below-ground structures.

Newton Waterproofing’s cavity drain systems are designed to meet and exceed these standards, ensuring compliance and peace of mind for architects and specifiers.

Empowering Architects and Specifiers with Advanced Cavity Drain Membrane Solutions

Cavity drain membrane systems represent a pinnacle in modern waterproofing technology, offering reliable, maintainable solutions for below-ground structures. As an architect or specifier, understanding these systems is crucial for delivering projects that stand the test of time and water pressure.

Newton Waterproofing’s extensive experience and comprehensive range of cavity drain membrane products provide the tools and expertise needed to tackle even the most challenging waterproofing projects. By mastering the application of these systems, you can ensure your designs not only meet but exceed client expectations and industry standards.

Remember, effective waterproofing is not just about product selection; it’s about comprehensive design, meticulous installation, and ongoing maintenance. With the knowledge gained from this guide and the support of Newton Waterproofing’s technical team, you’re well-equipped to implement cavity drain membrane systems that offer long-lasting protection and peace of mind.

For more information on our cavity drain membrane systems or to discuss your specific project requirements, don’t hesitate to contact Newton Waterproofing. Our team of experts is ready to assist you in creating dry, safe, and durable below-ground spaces.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.