01732 496 523

In the realm of basement waterproofing, few components play as crucial a role as the sump pump system, and for architects and specifiers working on projects involving below-ground spaces, understanding the intricacies of sump pumps is not just beneficial – it’s essential.

This guide to sump pumps will delve into the world of sump pumps, exploring their significance in basement waterproofing and highlighting best practices for installation and maintenance.

Whether you’re designing a new build or retrofitting an existing structure, this article will equip you with the knowledge to make informed decisions about sump pump systems.

The Importance of a Sump Pump in Basement Waterproofing

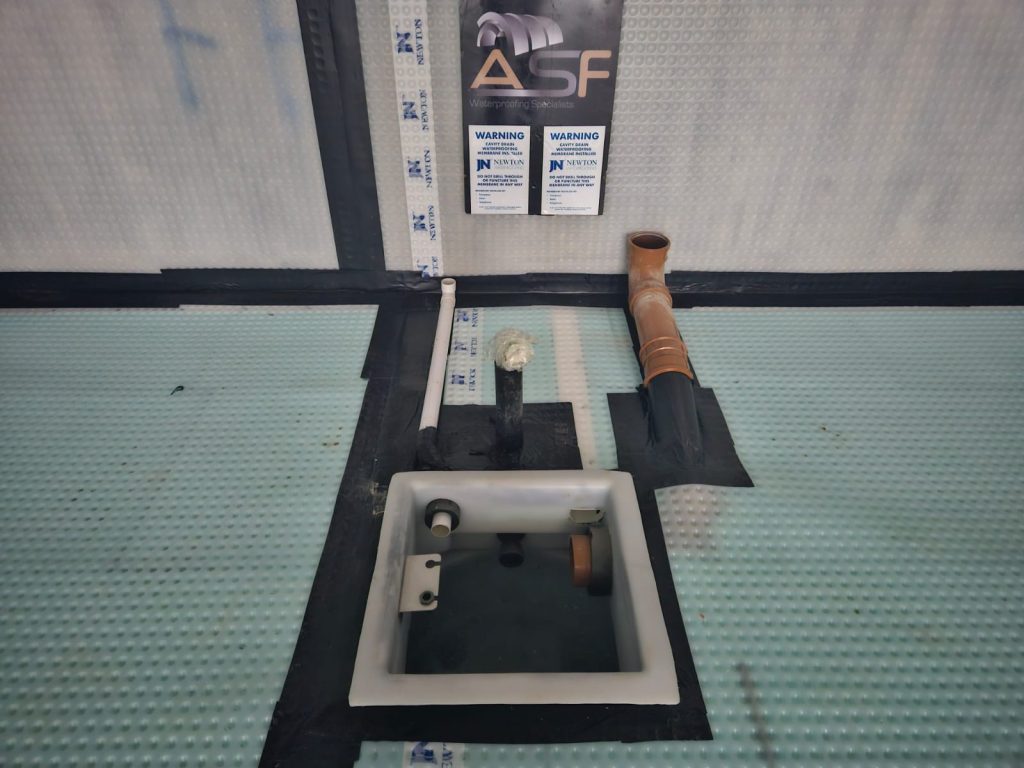

Sump pump units are a crucial component of cavity drain waterproofing, or ‘Type C’ systems, working tirelessly to keep below-ground spaces dry and habitable. They consist of a sump chamber, typically located at the lowest point of a basement or cellar, which houses two submersible pumps.

The primary function of a sump pump system is to remove groundwater that has managed to seep through the structure and has been captured by the cavity drain system.

By efficiently pumping out collected water, they play a critical role in preventing water ingress from affecting and damaging below-ground spaces, and mitigating the risks associated with high water levels. The importance of high-quality basement sump pump systems cannot be overstated, as they are essential in protecting basements and cellars from groundwater and potential flooding where Type C systems have been employed.

In the UK, where groundwater and flooding can be a significant concern in many areas, sump pumps are an indispensable tool in the specifier’s arsenal. They form a key component of a comprehensive cavity drainage system, working in tandem with other waterproofing measures to ensure the long-term integrity of basement structures.

By continuously monitoring and controlling water levels, the sump pump system including its submersible pumps, provides a proactive solution to potential water damage, safeguarding habitable spaces and their contents from ground water intrusion.

In addition, a separate sewage sump and pump system may also be necessary for below-ground properties with a requirement to remove foul water, ensuring that any waste is properly and safely removed from the basement.

What are Submersible Pumps and Why are They Important?

Submersible pumps are designed to operate while fully submerged in water. Waterproofing systems that include these robust units are typically the preferred choice for most basement waterproofing applications due to their numerous benefits:

- Quiet operation: Being submerged in water, housed within the sump and below a sealed lid and frame, these pumps produce minimal noise, making them ideal for residential settings.

- Space-efficient: Installed within the sump pit, the compact units don’t take up valuable floor space in the basement.

- Lightweight: They are specifically designed to be easy to handle and access, ensuring that future servicing and maintenance is achievable.

- High efficiency: Submersible pumps can handle higher volumes of water and often have superior pumping capabilities.

- Durability: Many models are constructed with corrosion-resistant materials like stainless steel, ensuring longevity even in harsh conditions.

Newton Waterproofing’s range of submersible pumps, such as those used within the Titan-Pro sump chamber for cavity drain waterproofing, exemplifies the high-quality, heavy-duty pumps suitable for both domestic and commercial applications.

Selecting the Right Pump

When specifying a sump pump, several factors need to be considered:

- Flow rate: This is the volume of water the pump can move, usually measured in litres per second. The required flow rate will depend on the expected water ingress and the size of the drainage area.

- Pumping head: This refers to the vertical distance the pump needs to move water. The duty chart of the pump should be referenced to ensure that the selected pump will be operating within the middle third of the pump curve. Generally, pumps with large diameter discharge will pump higher volumes at lower pumping head and pumps with smaller diameter discharge will pump lower volumes of water to higher pumping heads.

- Type of water: Different pumps are designed for clean water, grey water, or sewage. Ensure the specified pump matches the type of water it will be handling.

- Power source: Where continued pumping is critical, such as with basements protected by Type C, cavity drain systems, consider a battery backup system to ensure continued pumping when power outages occur.

- Material: For longevity and reliability, opt for pumps manufactured with high-quality materials like stainless steel which offer excellent corrosion resistance.

Whilst this may sound like a lot to consider, by working with an experienced, specialist and qualified waterproofing designer, you can trust that these considerations are taken into account as part of the overall system design.

The Crucial Role of Specialist Installation for a Sump Pump

When it comes to implementing sump pump systems, the expertise of the installer is just as vital as the quality of the components. Employing a specialist, trained, and qualified installer offers numerous benefits and is essential for ensuring the longevity and effectiveness of your waterproofing solution.

Why Choose a Specialist Installer?

- Expert Knowledge: Specialist installers possess in-depth understanding of sump pump systems and their integration with cavity drain waterproofing. This expertise ensures that the system is designed and installed to work seamlessly with the overall waterproofing strategy.

- Tailored Solutions: Qualified installers can assess your specific project requirements and design a bespoke sump pump system. They consider factors such as expected water ingress, basement size, and building structure to create an optimal solution.

- Installation Guarantees: Many specialist installers offer meaningful, insured guarantees on their work. This provides you with additional peace of mind and protection for your investment.

- Professional Indemnity Insurance: Reputable installers carry Professional Indemnity (PI) insurance, offering further protection against potential issues arising from the design or installation process.

- Compliance Assurance: Specialist installers are well-versed in relevant building codes and industry standards, ensuring that the installation complies with all necessary regulations, including Part P of the Building Regulations.

- Ongoing Support: By choosing a specialist installer, you gain a partner who can provide ongoing maintenance and support, ensuring the long-term performance of your sump pump system.

Newton’s Network of Specialist Basement Contractors (NSBCs)

At Newton Waterproofing, we recognise the critical role that expert installation plays in the success of our sump pump systems. That’s why we’ve established a nationwide network of Newton Specialist Basement Contractors (NSBCs).

Our NSBCs are:

- Thoroughly trained in the design and installation of Newton waterproofing systems, including sump pump installations

- Regularly assessed to ensure they maintain high standards of workmanship

- Capable of providing comprehensive installation guarantees

- Supported by Newton’s technical team for complex projects

By choosing an NSBC for your sump pump installation, you’re not just getting an installer – you’re gaining a waterproofing partner with the backing of Newton’s 170+ years of industry experience.

The use of a specialist installer is not just a recommendation; it’s a crucial step in ensuring the success of your waterproofing project. Their expertise, combined with Newton’s high-quality products, creates a formidable defence against water ingress in below-ground structures, providing you with the peace of mind that your basement will remain dry and protected for years to come.

Best Practice for Sump Pumps and Maintenance

To ensure the long-term functionality of sump pump systems, regular maintenance is essential. As a rule of thumb, the pumping system should have its first service within 3 months of being commissioned, and at this first visit a future service schedule should be agreed between the service engineer and the client:

Sump Pump Service Inspections

Sump chambers should be installed in locations that allow for easy access during the periodic servicing schedule.

The servicing and maintenance of Type C systems should be carried out by trained, competent service engineers, with a good knowledge of Type C waterproofing and access to the specific details of the installed system.

At first, Type C systems should initially be inspected and serviced at least annually, however in some circumstances the period between services may be considerably shorter or longer. Site conditions, design, materials, the machinery used, and the severity of the implications of a system failure will all play a part when deciding on the frequency and scope of service visits.

Battery Backup Maintenance

For installation with battery backup systems, these should also be checked and tested as part of the same agreed service schedule as the sump and pump system. With systems that use a control panel to operate manual submersible pumps, many panels include a feature that test the pumps on a regular basis and alerts the client of any issues with the pump health.

Alarm System Checks

Test any high-water alarms or remote monitoring systems to ensure they’re functioning correctly.

Discharge Point Maintenance

Regularly inspect the discharge point to ensure it’s clear of obstructions and directing water away from the building.

Water Precautions

In colder regions, take steps to prevent the discharge pipe from freezing, which could cause system failure.

Ensuring Long-Term Basement Waterproofing Success with a Sump Pump

Sump pumps are a critical component in effective Type C basement waterproofing designs. For architects and specifiers, understanding the types, applications, installation processes, and maintenance requirements of these systems is crucial for designing resilient below-ground spaces.

By leveraging high-quality products like those offered by Newton Waterproofing and following best practices in design and maintenance, professionals can ensure long-lasting, reliable waterproofing solutions for their projects.

As the UK’s oldest independent waterproofing company, we continue to lead the industry with innovative solutions and expert support.

Whether you’re working on a small residential conversion or a large-scale commercial development, partnering with experienced waterproofing specialists can make all the difference in achieving successful, dry basement spaces that stand the test of time.

Customer Success Stories

Our latest customer reviews from Feefo - the award winning review platform

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.