01732 360 095

In the world of construction and architecture, ensuring a watertight basement structure is paramount in achieving a completely dry internal basement area. External basement waterproofing that utilises quality waterproofing products, stands as the first line of defence against water ingress, hydrostatic pressure, and potential damage caused by ground water.

This guide summarises some of the intricacies of external waterproofing systems, considers best practice for architects and specifiers, and explores Newton’s advanced solutions.

Understanding External Basement Waterproofing

Put simply, external basement waterproofing involves applying a waterproofing barrier to the exterior of a basement structure to prevent water penetration. The aim of this method is to stop water before it can even reach the structure, providing robust protection against ground water.

The Importance of BS 8102:2022 Compliance

When considering external waterproofing options, compliance with BS 8102:2022 is crucial. British Standard 8102:2022 is the Code of Practice for the Protection of Below Ground Structures Against Water Ingress, and it provides key recommendations and guidance for designing and specifying waterproofing systems.

Defined as ‘Type A’ barrier systems by BS 8102:2022, external basement waterproofing can be anything from a sheet or liquid membrane to a cement render or slurry. However, regardless of the type of product, it is important to consider the typical defects that may occur in Type A waterproofing systems, as explained by the British Standard. These include:

- defects owing to design;

- defects owing to poor workmanship;

- inappropriate use of the materials being used and defects owing to the specific properties of the materials being used

- defects caused by follow-on trades and site operations.

With these in mind, and if your aim is to completely prevent water from entering a below-ground structure, then only a fully bonded external waterproofing membrane should be used.

Newton’s Advanced External Waterproofing Systems

The Newton HydroBond System offers a range of innovative pre-applied and post-applied membranes designed to provide superior external waterproofing protection. These include:

HydroBond 403 & HydroBond Lite:

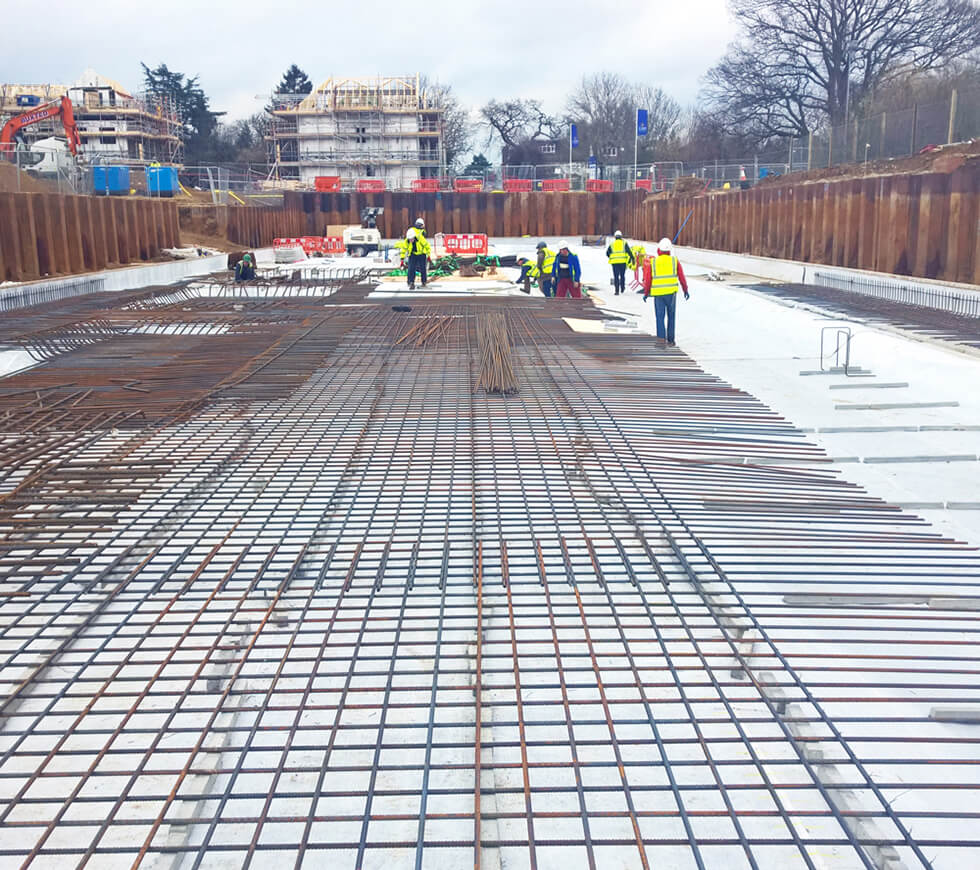

Pre-applied membranes that form a permanent mechanical bond with freshly poured concrete, creating a waterproof envelope around the entire below-ground structure:

- Full mechanical bond to concrete to prevent water migration

- HydroBond 403 has a hydrophilic layer that will self-heal when punctured, and also features a gas rated variant, HydroBond 403 GB

- Flexibility to resist movement and fissures in substrates

- Excellent resistance to the high alkalinity of concrete

- HydroBond Lite acts as a radon barrier

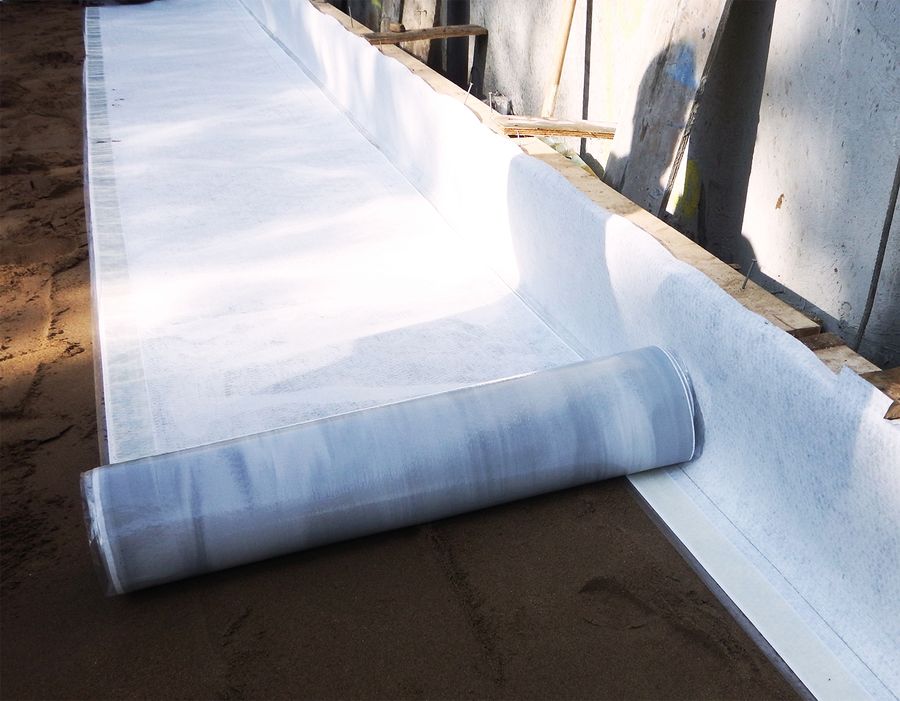

A self-adhesive sheet membrane that is post-applied to the below-ground concrete or block walls with exceptional peel adhesion and crack-bridging qualities:

- Resistant to aggressive ground water chemicals

- Tough and durable

- Stable and flexible for easy detailing

- High resistance to radon

- Quick and simple to install – no jointing tapes

- Gas variant also available

A liquid-applied external basement waterproofing membrane that is post-applied to earth-retaining structures to form a thick, highly flexible barrier to water and radon:

- Fully bonded seamless waterproofing membrane

- Flexible with 2 mm crack bridging capabilities

- Easily applied by trowel or spray machine

- Quick-drying and rain-fast after a short period

- Radon gas resistant

These innovative membranes showcase Newton’s commitment to providing cutting-edge waterproofing solutions that meet the diverse needs of modern construction projects.

Factors Influencing Waterproofing System Selection

Choosing the right external waterproofing system depends on several factors:

- Site Conditions: Soil type, water table level, and drainage characteristics play a crucial role in system selection.

- Building Methods: The construction technique, whether cast-in-situ concrete, precast panels, or other methods, influences the choice of waterproofing system.

- Access to Structure: The ease of access to the external walls during and after construction impacts the feasibility of certain waterproofing methods.

- Desired Internal Environment: The intended use of the basement space and required level of dryness guide the selection of appropriate waterproofing solutions.

- Budget Constraints: While not compromising on quality, budget considerations may influence the choice between different waterproofing options.

By carefully evaluating these factors, architects, specifiers and specialist waterproofing designers can select the most appropriate external waterproofing system for their specific project needs.

What Are the Key Benefits of External Basement Waterproofing?

External basement waterproofing offers several advantages, including protection against hydrostatic pressure, prevention of water, radon and gas ingress, preservation of structural integrity, and creation of a dry internal environment.

When installed correctly, perhaps the primary benefit of these membranes is the creation of a continuous, homogenous barrier that delivers a robust first form of defence against water.

Implementing External Waterproofing: Best Practices

To ensure the effectiveness of external waterproofing systems, consider the following best practices:

- Proper Surface Preparation: Ensure the substrate is clean, dry, and free from defects before applying the waterproofing membrane.

- Accurate Detailing: Pay close attention to corners, joints, and penetrations, using appropriate accessories and sealants.

- Protection During Backfilling: Install protection boards, insulation or drainage membranes to shield the waterproofing membrane during backfilling operations.

- Integration with Drainage Systems: Where the sloping site allows for removal of water downhill of the property, incorporate appropriate drainage solutions, such as French drains or drainage sheet membranes, to divert water away from the structure.

- Quality Control: Conduct thorough inspections and testing to verify the integrity of the waterproofing system before completing the construction process.

Synergy Between External and Internal Waterproofing

While external waterproofing provides primary protection, a holistic approach to basement waterproofing often involves combining external and internal systems. This is particularly relevant when the aim is create a completely dry ‘Grade 3’ internal environment.

Our comprehensive range of waterproofing solutions allows for the integration of:

- Cavity Drainage Systems: Type C waterproofing, often requiring a pumping system, that collects and removes any water that penetrates the structure, providing a secondary form of waterproofing.

- Cementitious Waterproof Coatings: Applied internally, these Type A coatings offer additional protection and can be used in conjunction with external membranes.

By combining these systems, architects can create a robust, multi-layered approach to basement waterproofing, significantly reducing the risk of water ingress and damage.

Addressing Common Challenges in External Waterproofing

External basement waterproofing can present unique challenges that require careful consideration:

- High water Tables: In areas with high water tables and where the topography allows removal by gravity, additional measures such as land drains and robust waterproofing membranes may be necessary to combat increased hydrostatic pressure.

- Limited Site Access: For projects with restricted access to external walls, post-applied membranes such as Hydrobond SA or liquid-applied membranes like HydroBond 2K-Flex can provide an effective solution.

- Complex Geometries: Unusual basement shapes or structures with multiple penetrations may require a combination of sheet membranes and liquid-applied products for comprehensive coverage.

- Contaminated Sites: In brownfield developments or areas with soil contamination, gas barrier membranes like HydroBond 403 GB and HydroBond SAGM can provide dual protection against water ingress and harmful gases.

Safeguarding Structures: The Future of External Basement Waterproofing with Newton

External basement waterproofing is a critical aspect of modern below-ground construction, providing essential protection against water ingress.

For specifiers, ensuring the long-term integrity and performance of basement structures is as simple as leveraging Newton’s advanced waterproofing systems and design services, providing compliant specifications and following best practice,

From innovative pre-applied membranes like HydroBond 403 to versatile liquid-applied barriers such as HydroBond 2K-Flex, the Newton HydroBond System offers a comprehensive range of external waterproofing options that meet diverse project requirements. By carefully considering site conditions, building methods, and desired outcomes, professionals can select the most appropriate system for their specific needs.

As the industry continues to evolve, Newton remains at the forefront of waterproofing technology, combining cutting-edge solutions with sustainable practices to address the challenges of modern construction.

Contact Newton Waterproofing today for expert guidance on selecting and implementing the ideal external waterproofing system for your project. Our team of specialists is prepared to provide tailored solutions that ensure the long-term success of your construction endeavours.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.