01732 360 095

Sustainability is becoming an increasingly pressing matter within the construction industry. With rising concerns over carbon emissions, energy consumption and the depletion of natural resources, construction companies must implement sustainable practices in order to reduce our environmental impact.

Through pioneering recycling initiatives, eco-friendly product developments, and a commitment to environmental protection, we are proud to be setting new standards for sustainability in structural waterproofing.

The Newton Recycling Service: A Game Changer for the Industry

In 2017, we pioneered the first closed-loop waste management and recycling service in the UK waterproofing industry. Now having recycled over 26 tonnes of material, the initiative addresses the problem of the waste that is generated from waterproofing membranes and product packaging, providing a practical, eco-friendly solution for contractors and construction companies.

How Does Newton’s Recycling Service Work?

The process of installing waterproofing products inevitably generates off-cuts, unusable packaging and waste materials. However, rather than allowing these to contribute to landfill waste, our recycling service ensures that they are collected, reprocessed and recycled. The service operates by:

Collection of Waste Materials

Thanks to our own fleet of delivery vehicles, Newton’s specialist drivers collect membrane off-cuts and empty packaging from our nationwide network of Newton Specialist Basement Contractors (NSBCs). These collections coincide with deliveries of new product, thereby reducing the need for separate journeys and minimising carbon emissions.

Sorting and Recycling

The collected materials are returned to our headquarters, where they are processed and prepared for recycling.

Reintegration into the Industry

The prepared materials are sent to a third-party plastics reprocessor, where they are manufactured into new construction products and reintroduced into the supply chain. In doing so, we are contributing to the use of recycled and renewable materials in future building projects.

The Environmental and Commercial Benefits for Contractors

Participating in Newton’s sustainable construction initiative offers numerous benefits to contractors and construction companies:

- Reduction of waste disposal costs – Contractors can lower expenses related to waste disposal, improving their bottom line.

- Minimised carbon footprint – By recycling waterproofing membranes, contractors help lower the gross annual carbon emissions associated with their construction projects.

- Enhanced corporate social responsibility – Demonstrating a commitment to sustainability in construction aligns contractors with global and UK environmental regulations, which is increasingly important to stakeholders.

- Compliance with Green Building Standards – The initiative contributes to green certifications such as BREEAM, helping to create sustainable buildings that meet the Future Homes Standard.

Newton’s Commitment to Sustainable Product Development

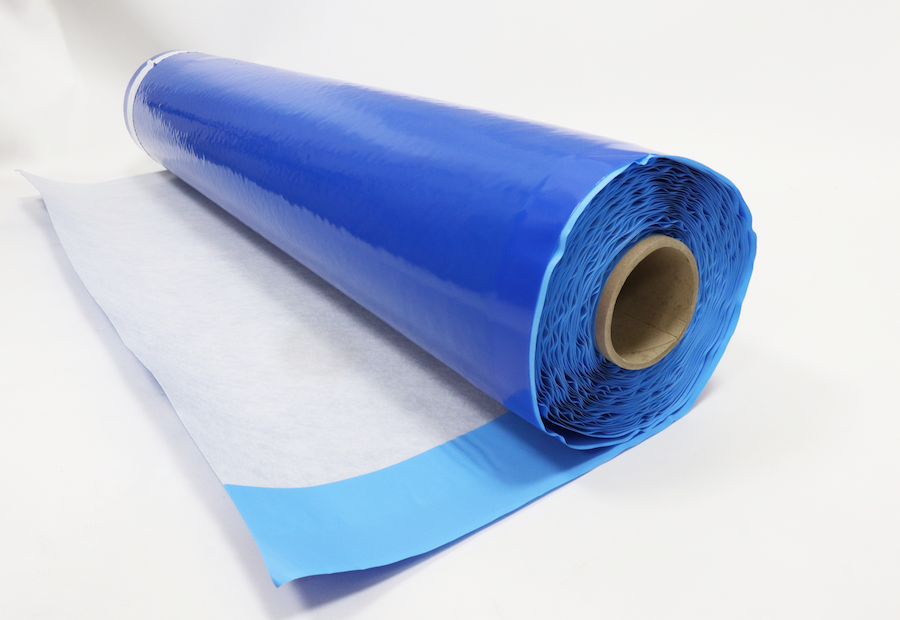

Beyond recycling, we are dedicated to producing sustainable building materials that reduce energy consumption and promote resource efficiency. This is evident in our latest Environmental Product Declarations (EPDs) for the HydroBond 402 and HydroBond 403 external waterproofing membranes.

What Makes These Products More Sustainable?

Newton’s EPD-certified products further contribute to the reduction of the environmental impact of waterproofing systems by:

- minimising fossil fuel usage during production

- extending material lifespans

- reducing amount of waste, and

- promoting energy efficiency

Overall, these EPD certified products ensure less energy consumption while supporting sustainable building materials and responsible use of resources.

The Impact of Newton’s Recycling Service on the Built Environment

Since its launch, our waste management programme has made a positive impact on green construction. Some of the key outcomes include:

- Reduction in landfill waste, ensuring less energy is used in waste disposal.

- Significant carbon footprint reductions, as the recycling initiative limits unnecessary material production.

- Greater use of sustainable materials, incorporating renewable materials into new building projects.

- Improved quality, as more environmentally responsible materials contribute to healthier and more sustainable buildings.

The Essential Role of Sustainability in Construction

As the UK government continues to push for sustainable development, construction companies play an essential role in fostering sustainable construction methods. By integrating sustainable practices such as recycling and EPD-certified construction materials, we are helping to shape a construction sector that is willing to change its approach to environmental sustainability and long-term performance.

Join the Newton Recycling Service Today

For specialist waterproofing contractors looking to reduce waste and contribute to a more sustainable waterproofing industry, consider joining our Recycling Service. Together, we can drive green construction forward, minimise waste, and create sustainable buildings that stand the test of time.

Watch the video to learn more about Newton’s sustainability initiatives:

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.