High-density polyethylene (HDPE) plastic, known for its ease of melting and moulding, offers a wide range of applications. HDPE, a thermoplastic polymer, is commonly used in packaging, construction and automotive industries.

It can be found in plastic bottles, milk bottles, shampoo bottles and detergent bottles. Its resistance to chemicals and moisture makes it suitable for various industrial applications. Furthermore, HDPE’s recyclability and high-density ratio add to its appeal.

Corrosion resistance

High-density polyethylene (HDPE) is a versatile thermoplastic polymer known for its excellent corrosion resistance. It finds wide application across industries such as chemical processing, water and wastewater treatment, and food and beverage packaging. With its ability to withstand corrosive substances, HDPE ensures a longer lifespan for products and reduces maintenance costs.

It is commonly used in underground applications, storage tanks, and liners, providing reliable containment solutions. The corrosion resistance of HDPE, combined with its ease of fabrication and wide range of applications, makes it a durable and cost-effective choice. (

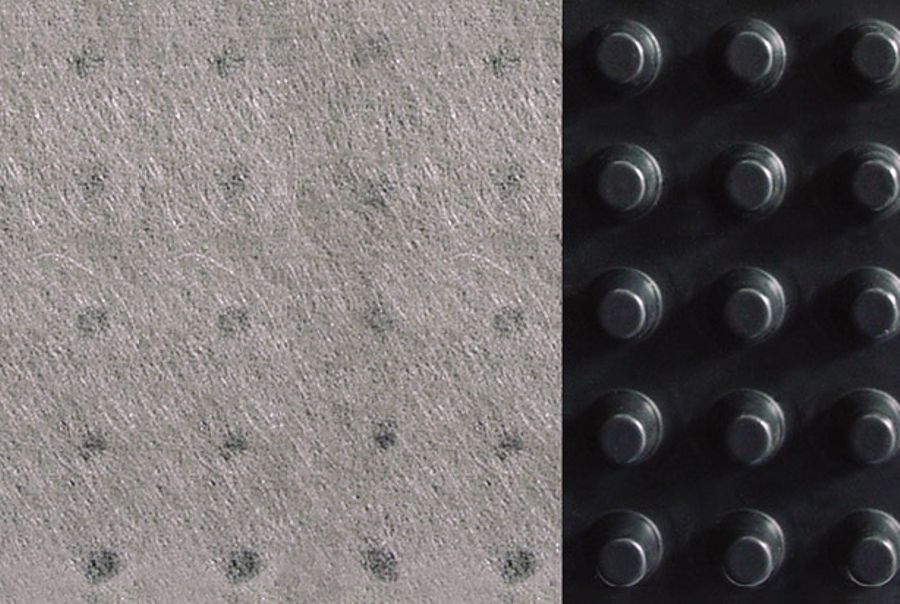

Large strength-to-density ratio

The exceptional strength-to-density ratio of HDPE plastic is well-suited for a wide variety of applications. Its high tensile strength and durability make it an ideal choice for industrial applications such as pipe systems and packaging. HDPE, also known as high-density polyethylene, is widely used in the manufacturing of plastic bottles, milk jugs, and shampoo bottles.

Its ease of fabrication and resistance to moisture absorption make it a favoured material for food storage containers and beverage containers. The density ratio of HDPE contributes to its lightweight nature, allowing for easy handling and transportation. Moreover, HDPE’s recyclable nature promotes sustainability and is a crucial aspect of plastic recycling efforts.

Easily recycled material

Recycling is an essential aspect of HDPE plastic. With its high density and polymer composition, HDPE is a thermoplastic polymer that can be easily melted down and moulded into new products. By recycling HDPE, we can minimise the use of petroleum-based materials and reduce environmental impact. From plastic bottles like milk jugs and shampoo bottles to containers for detergents and motor oil, HDPE can be transformed into a wide range of applications.

This versatile material’s resistance to moisture and solvents, as well as its high density and tensile strength, make it ideal for food storage containers, bins, and even plastic lumber. With its low melting point and ease of fabrication, HDPE is a preferred choice for sustainable packaging and industrial applications and leads to fewer trips to landfill sites.

Reasons to use HDPE

A versatile thermoplastic polymer, HDPE offers a wide variety of applications. With its high strength-to-density ratio and resistance to chemicals, moisture, and UV radiation, HDPE is a durable choice for outdoor applications. Its recyclability and lower environmental impact make it a sustainable option.

HDPE’s ease of fabrication, lightweight nature, and wide range of industrial applications further enhance its appeal. From bleach bottles and food storage containers to pipe systems and packaging, HDPE’s versatility and durability make it a top choice in many industries.