- Instant, Permanent Watertight Seal: HydroTank 301-EP Metal Waterbar provides an immediate, permanent watertight seal with its adhesive, reactive polymer coating, ensuring robust protection against water infiltration.

- Effortless Installation, Maximum Efficiency: Quick and easy to install with special clips to reinforcement steel, HydroTank 301-EP eliminates the need for traditional kickers, embedding seamlessly within concrete for effective water blockage.

- Superior Water Pressure Resistance: Certified to withstand up to 5 bar (50m) of water pressure and resistant to all naturally occurring groundwater types, HydroTank 301-EP ensures durable, versatile protection for concrete structures.

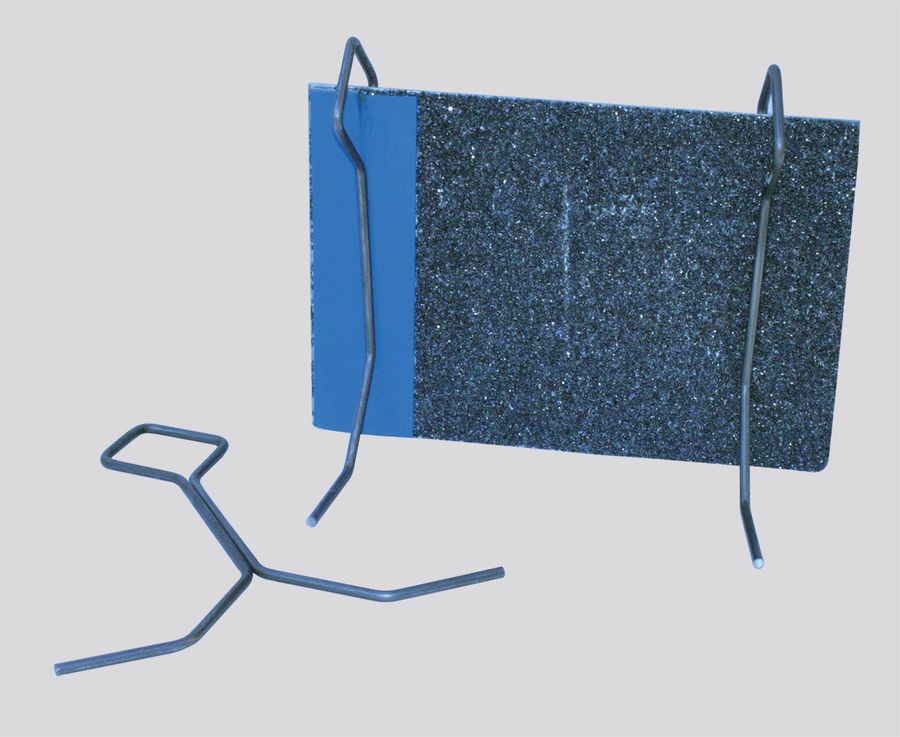

Coated metal waterbar system used for sealing kickerless construction joints within retained concrete structures. It features an adhesive, reactive polymer coating on one of its sides which creates a permanent watertight seal that works immediately.

Installation is quick and easy with the waterbar fitted in place to the reinforcement steel with special clips so that after the placement of the concrete, the waterbar is fully embedded within the two adjoining elements, completely blocking the passage of water through the joint.

Because HydroTank 301-EP Metal Waterbar is not fixed to one of the concrete elements as is the case with conventional waterbars, the forming of a kicker is not necessary. Where the walls are formed above a kicker joint, use 315 Polymer Waterbar.

Newton HydroTank 301-EP Metal Waterbar is certified to resist water pressure of up to 5 bar (50m), and is resistant to all types of naturally occurring ground water types.