- Effective Water Sealing – Prevents water ingress through construction and movement joints in concrete structures.

- Durable & Flexible – High-performance PVC formula ensures longevity and adaptability to structural movements.

- Versatile Application – Suitable for both water-retaining and water-resisting structures.

HydroTank XTCB and HydroTank XTRS are traditional, cast in-situ PVC WaterStops, designed to provide a watertight seal to prevent water passing through construction and movement joints of concrete structures. HydroTank XTCB is installed to the centre of the concrete section of the joint and HydroTank XTRS is applied to the external face of the joint.

The waterstops and their ancillaries are extruded from a high-performance PVC formula which has excellent flexibility and longevity. The multi-rib profile provides a torturous path to prevent the passage of water through joints when concrete is correctly placed and compacted.

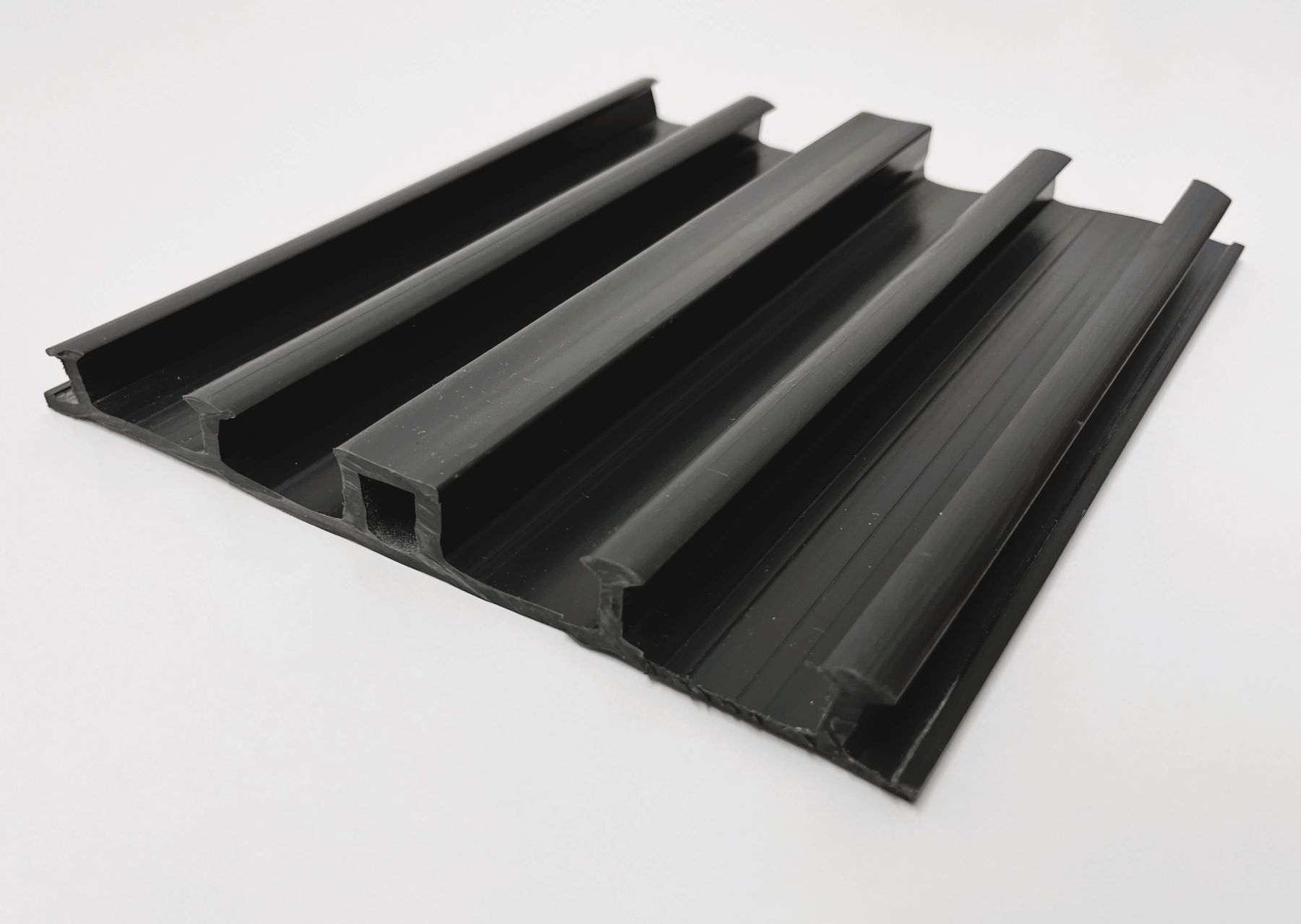

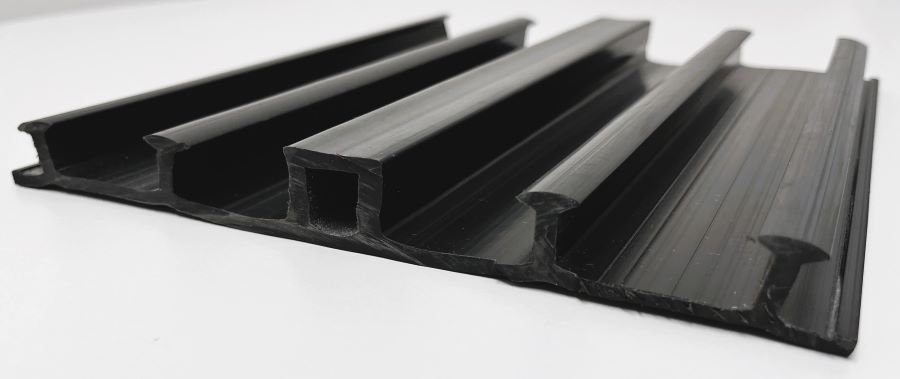

HydroTank XTCB

The XTCB profile is specifically developed to be placed centrally within concrete wall and floor joints, and includes an eyelet edge flange which enables wiring and positioning to the surrounding reinforcement. Placed centrally within the joint, the XTCB is able to withstand water pressure from either side, making them suitable for both water retaining and water resting structures. The XTCB also has a central bulb to accommodate the movement in expansion joints and the support of the joint filler board.

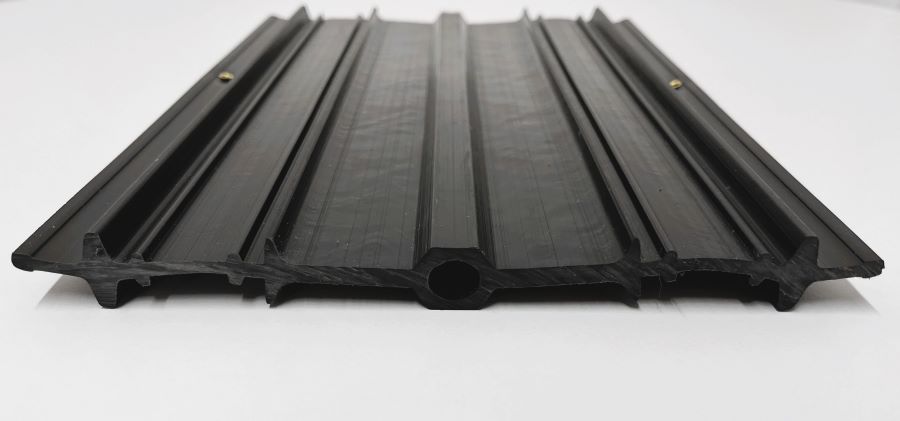

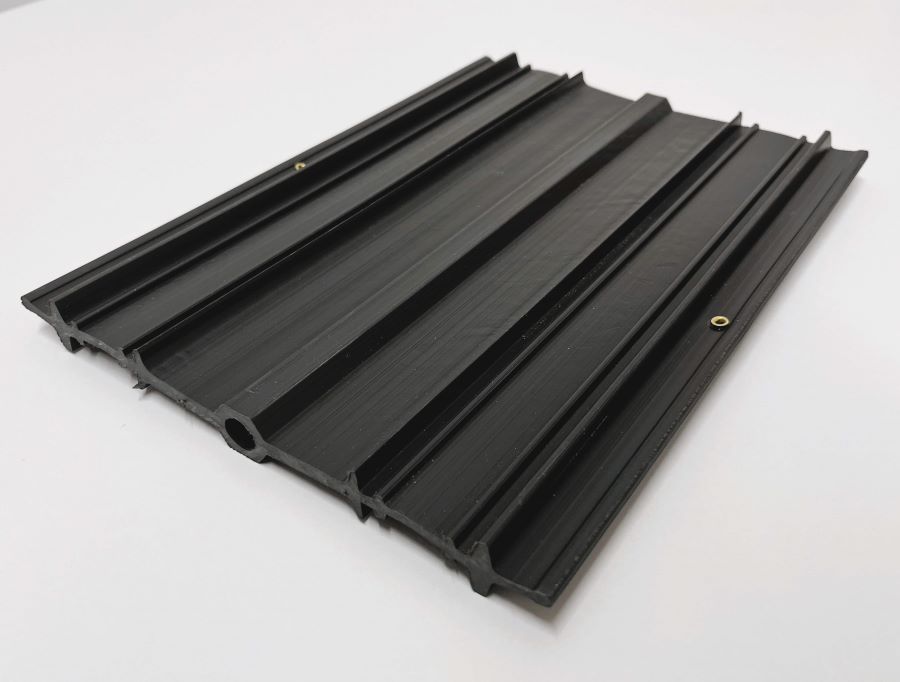

HydroTank XTRS

The XTRS profile is specifically developed to seal joints in concrete at the external surface which protects the reinforcing steel against corrosion attack and provides a totally watertight seal. The central bulb allows movement to be accommodated in expansion joints and also provides an area to support expansion joint filler boards. The XTRS incorporates a nailing flanged edge to ensure a secure fixing that resists tearing.

When used in walls, externally placed waterstops will only resist water pressure from the face to which they are fixed. When used below floor slabs, where the waterstop is supported by the building concrete or when placed in vertical situations against permanent concrete shuttering, externally placed waterstops will resist water pressure from either face.