Pre-Bagged, One-Coat Waterproofing System

... Read more

01732 360 095

System 100

System 200

System 300

Injection Hose Systems

System 400

System 500

System 600

System 700

System 800

System 900

Pumps and Controls

A range of BBA approved damp proof membranes, coatings and ancillaries which are quick and clean to install and offer a permanent solution for damp proofing above-ground walls.

Newton supplies a selection of damp proofing membranes for above ground applications. These membranes isolate the new internal surfaces from any dampness within the wall, ensuring that it will never be affected by moisture or salts.

For example, Newtonite 803 membrane is used where the wall finish is timber battens, a dry-lining frame or a block wall. On the other hand, the Newtonite Lath provides a mechanical key for plasters, renders, and dot and dab plasterboard.

When installing damp proofing solutions, specialist ancillary products are critically important for achieving a correct installation. Newton’s comprehensive range of ancillary products includes all of the essential items such as fixing plugs, sealing tapes, and liners for joists, back-boxes and pipes.

Another example is Newtonite 801 Mastic, a multi-purpose product that seals penetrations through the Newtonite membranes, preventing a bridge between the damp substrate and the internal surface.

Have a read of these projects where our products were used to achieve a comprehensive damp proofing solutions:

Diasen C.W.C. Stop Condense is a white thermal coating for cold and poorly insulated surfaces. By warming the surface of the treated wall it prevents the formation of internal condensation and therefore also prevents the occurrence of mould.

Diasen BKK is a transparent and colourless wall coating that protects exposed external walls against driving rain and associated moisture penetration. The resultant dry wall is highly resistant to weathering and UV.

The most effective way to damp proof walls using damp proof paint is by first applying the paint to the underlying surface and then covering it with a layer of render or plaster. This method forms a sandwich system that retains the damp proof layer within the structure of the wall, preventing the intrusion of moisture.

Click on the boxes below to find out more about Newton’s Damp Proofing products

A range of liquid applied protective and decorative internal flooring products. These coatings are fast curing, available in a variety of colours, and are typically used for the refurbishment and protection of commercial and domestic floors.

Liquid waterproof coatings provide a fast-curing, straightforward and effective method for internal flooring protection.

At Newton, our coatings are compatible with both residential and commercial applications, and offer customers a cost-effective method for creating a durable floor coating or internal lining.

Newton Epoxy Top Coat is a solvent-free floor coating that has excellent adhesion and can provide protective and decorative properties to concrete, steel and other substrates.

The cured coating creates a tough and durable layer with excellent chemical resistance, suitable for a wide range of different applications including manufacturing units, food preparation areas, and industrial buildings.

Have a read of this project where Newton floor coatings were installed:

Our polyurea waterproof coating is a solvent-free, hot spray coating that cures into a flexible and impermeable membrane with outstanding chemical resistance properties.

The coating is ideal for repairing and protecting soil pipes, drainage canals, drainpipes, tank farms, industrial floorings, roof coverings, parking lots, conveyers, pavements, retention pounds, and bridges, amongst other applications.

Click on the boxes below to find out more about Newton’s waterproof coatings.

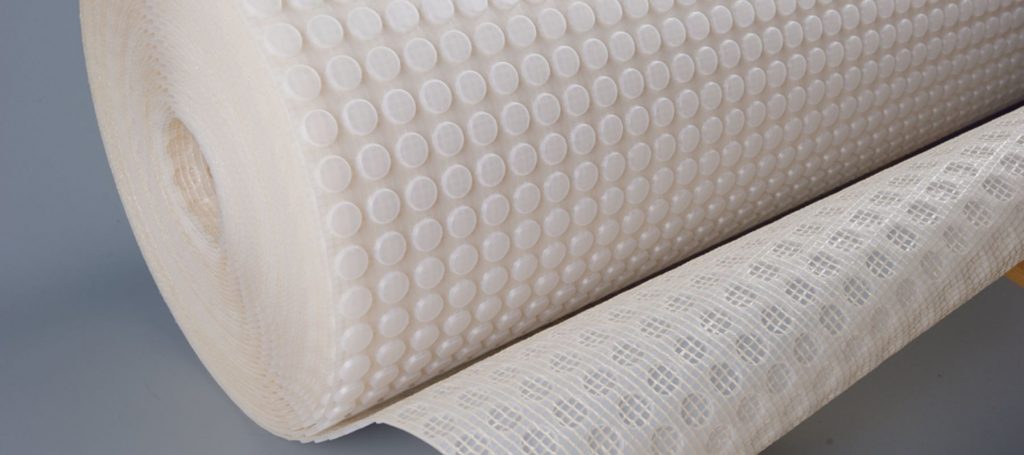

A range of HDPE and HDPP sheet flooring membranes which provide a damp proof solution for commercial and domestic floors. The membranes protect the floor finish by ‘decoupling’ it from the substrate, preventing damage as a result of movement and/or cracking.

Both Newton’s HDPE and HDPP waterproofing membranes provide excellent protection against water and water vapour; isolating internal flooring from dampness below, as well as contaminants such as alkalies, hydrocarbons, saline solutions and organic acids.

Both materials offer effective waterproofing protection and can be used in conjunction with other Newton products. whilst also protecting against substrate movement

Newton DampSafe 601 Slimline and DampSafe 603 are loose-laid sheet flooring membranes of 1mm and 3mm thickness respectively. Both can protect flooring from damp slabs and contamination, and can also be used as part of the Newton CDM System below ground or with Newtonite damp proofing membranes above ground.

Newton DampSafe 603 Tile D-Mat is a 3mm decoupling mat that isolates the tiled floor surface from cracking or movement in the substrate, and prevents compressive stress from acting on specific points on the tiled floor.

The lightweight membrane is tough and durable, and the fleece surface on both sides absorbs tile adhesive to create an exceptional bond with both the subtrate below and the tiled floor above.

The use of sheet membrane offers the benefit of clear visibility, making it convenient to locate the membrane. Unlike liquid membrane, which can lead to unintended gaps in the seal during application, sheet membrane can be precisely cut to fit.

The Newton Cavity Drain Membrane (CDM) System is a maintainable basement waterproofing solution, certified to BES 6001 by BRE Global, ideal for new-build basements and refurbishment projects.

The Newton Cavity Drain Membrane (CDM) System is a maintainable basement waterproofing solution, certified to BES 6001 by BRE Global, ideal for new-build basements and refurbishment projects.

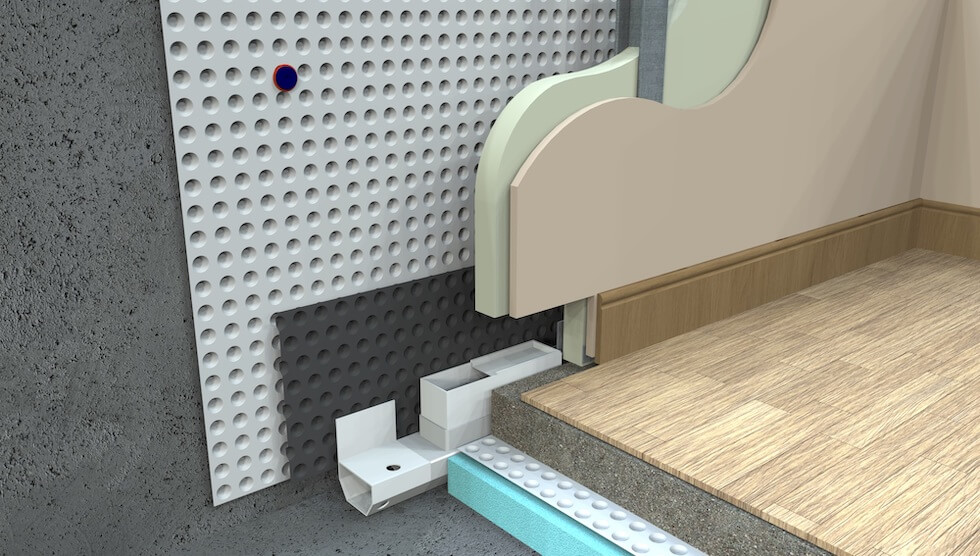

Comprising of four components: Cavity Drain Membranes, Drainage, Pumps and Control Systems, the Newton CDM System complies with the British Standard for Waterproofing and provides a Grade 3 habitable internal environment.

Cavity drain membrane (CDM) systems are a maintainable, internal basement waterproofing solution, suitable for protecting below-ground environments against water that has penetrated through the structure. CDM Systems are known as ‘Type C’ waterproofing in British Standard 8102:2022 and are ideal for new-build, refurbishment and historic/listed projects.

Known as the most failsafe form of waterproofing, the cavity drain membranes capture ingressing water at the point of ingress, then the CDM drainage system manages and directs the water to an integral pumping system or drainage outlet for safe removal.

The Newton PAC-500 System also provides a combined CDM waterproofing and gas proofing system for below ground spaces that are at risk from ground gases.

Once the water has been captured by the cavity drain membranes and drainage channels, it needs to be safely removed. The Titan-Pro is a packaged sump chamber and pump system designed specifically to be used with the Newton CDM System. Compatible with a variety of Newton pumps, it is ideal for almost any cavity drain waterproofing system.

Have a read of these projects where the Newton CDM System was successfully used:

The Newton CDM System requires a number of specialist ancillary products that are critical for correct installation. At Newton, we supply the full range of ancillary items that are used in conjunction with our cavity drain membranes, drainage and pumping systems.

The drained cavity system offers certified and failsafe basement waterproofing. It efficiently captures and removes water, ensuring a dry and protected environment. Its versatility makes it suitable for various projects, including new-builds, refurbishments, and historic buildings. The system also provides gas proofing capabilities for below-ground spaces. With compatible ancillary products and efficient water removal using pumps, the CDM System is a reliable and maintainable solution.

We provide cavity drain waterproofing products and solutions across the whole of the UK:

A selection of preformed external waterproofing and drainage membranes, and Newton’s flagship self-healing Type A membrane HydroBond 403 Plus. Used externally, these products provide waterproofing solutions for earth-retained structures and covered decks.

External waterproofing membranes are a range of liquid-applied and sheet membranes that can either be post- or pre-applied to the exterior surface of a below-ground or earth-retaining structure.

The membranes are categorised as a ‘Type A’ form of waterproofing as per British Standard 8102:2022, which are designed to resist hydrostatic pressure and prevent water passing through the structure and penetrating the internal environment.

Newton supplies a wide range of external waterproofing membrane products, including our flagship HydroBond 403 Plus self-healing sheet membrane.

Newton HydroBond 403 Plus is a high-performance self-healing membrane that creates mechanical bond with the structural concrete and provides a waterproof envelope around the structure. The gas barrier variant also protects against radon gas, carbon dioxide and various hydrocarbons.

HydroBond 403 Plus is often combined with other Newton products to provide a comprehensive structural waterproofing solution. As a continuous external Type A membrane it is pre-applied to raft and wall formwork prior to the placement of the reinforced concrete.

Have a read of these projects where Newton HydroBond 403 Plus was used:

Drainage membranes protect the external waterproofing membrane and the structure from water pressure, chemicals in the ground and from damage during backfilling.

Drainage membranes such as HydroBond 410 GeoDrain consist of a geotextile filter layer that is thermally welded to a HDPE drainage membrane. This drainage layer prevents water pressure from coming to bear against a structure, provides protection against damaging chemicals in ground water and filters out any suspended soil particles that might block the membrane.

Click on the boxes below to find out more about Newton’s external waterproofing and drainage membranes

A range of products used to waterproof construction joints and movement joints of retained concrete structures so that they become integrally waterproof.

Concrete joints are essential. They allow the concrete to shrink as it dries, preventing internal restraint which would lead to cracking, and they also allow it to expand and contract under different temperature conditions.

Whilst there are different types of concrete joints, if the structure is below ground then it needs to be protected against water ingress, and waterproofing products will be required to seal them. This is as well as any service or pipe penetrations and any cracks that may also appear in the concrete.

Concrete joint sealing products allow the structure to expand, contract and move without affecting its waterproofing integrity and even prevent contaminants in the soil from entering the structure.

Our innovative range of products can be used to waterproof joints in concrete and provide a Type B waterproofing structure that acts as the primary form of resistance to water ingress. This includes all below-ground structures, including tunnels, basements, water tanks, and podium decks.

Concrete injection resins are also an effective method of leak sealing in a wide range of scenarios. From creating Type B waterproof structures using injection hoses to repairing leaks and cracks in existing concrete structures.

Have a read of these projects where concrete joint and leak sealing were successfully addressed.

Newton 302 Injection Hose is a high-performance waterbar system for sealing construction joints in earth retaining and water retaining concrete structures. The waterbar is installed within the joint and, once the concrete is cured, an injection resin is pumped into the hose under pressure. The resin penetrates the surrounding concrete within the construction joint, and cures to create a permanent seal for any cracks, capillaries, pores, and honeycombing within the structure.

Depending on the injection requirement, Newton can supply the whole range of high quality acrylic and polyurethane resins from our specialist resin supplier Tradecc.

Click on the boxes below to find out more about Newton’s concrete joint and leak sealing products

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.