01732 360 095

Newton FlexProof System

The Newton FlexProof System is a highly advanced, single-component liquid waterproofing material, which forms an elastomeric polymer membrane that is rainproof in minutes and capable of handling severe building movements and deformations.

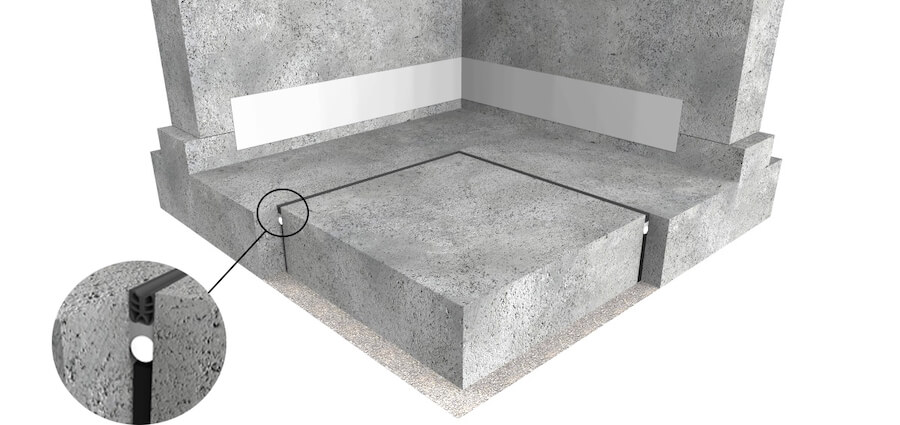

The FlexProof System is a specialist solution, comprising of products that have been designed and recommended together in order to deliver a robust and effective seal to both static and non-static construction joints. This includes an advanced liquid polymer membrane, a primer for porous surfaces, a movement joint profile, and a foam backing rod.

Type B Waterproofing

The British Standard for Waterproofing 8102:2022, the Code of Practice for the “Protection of Below Ground Structures Against Water Ingress” defines ‘Type B’ waterproofing as designing the structure itself to be integrally waterproof and the primary resistance to water ingress.

Well designed, well placed and reinforced concrete structures are the best form of primary water resistance, so long as it is designed in accordance with BS EN 1992. The use of the Newton FlexProof System forms part of this holistic view to waterproofing the whole structure, providing reliable waterproofing to the construction joints, in order to create a Type B structure that should be fully watertight in its own right.

FlexProof Membranes

- Suitable as a surface seal over joints

- Applicable in sub-zero temperatures and on damp substrate

- 100% waterproof but allows vapour diffusion

- Typically used within movement joints

- Very flexible and resistant to movement

- Excellent adhesion to suitable substrates

- No primer required

FlexProof System Ancillaries

- Primer for construction joint waterproofing

- Improves adhesion of FlexProof 106 to porous surfaces

- Seals porous and dusting concrete

- Movement joint profile

- Protects FlexProof 106-NV where there is a risk of mechanical damage

- Enhances the watertightness of the movement joint

-

- Foam backing rod for movement joints

- Ensure that FlexProof 106-NV is applied at the correct depth within the joint

- No adhesive or primer required

Combination Waterproofing

British Standard 8102:2022 recommends combining two or more Types of waterproofing for more robust waterproofing protection. Therefore, the Newton FlexProof System can be combined with various other Newton systems, including the CDM System, HydroBond System and HydroSeal System for Type C and external and internal Type A waterproofing respectively.

The Newton Technical Team will always ensure the end user’s desired internal environment is achieved with the right combination of structural waterproofing methods in accordance with current legislation and best practice. Professional waterproofing designers should always consider using more than one type of waterproofing to provide enhanced protection to the structure and achieve the necessary environmental grade.

FAQ

What are the types of construction joints?

There are three categories of joints: Contraction Joints, Construction Joints, and Isolation Joints. Among these, the most prevalent are contraction joints, which manage cracks resulting from restrained shrinkage, loads, and other stresses. The depth of the joint should be no less than ¼ of the thickness of the slab.

What is the purpose of a construction joint?

Construction joints are installed to secure newly poured concrete. These joints serve as screed rails, constructed from wood, metal, or plastic, and are placed during the pouring and finishing process of the concrete.

For more information on the Newton FlexProof System and to find the product best suited to your project requirements, please fill in the form below, or call our Technical Team on 01732 360 095 or email tech@newtonwaterproofing.co.uk.

Customer Success Stories

Our latest customer reviews from Feefo - the award winning review platform

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.