01732 496 523

When it comes to the challenge of waterproofing and gas proofing a below-ground structure, how do modern waterproofing products perform as an effective gas protection offering?

The answer to this question depends on several aspects, including the types of ground gases or contaminants that are present, as well as the contamination levels that are outlined in the site report that should be performed on any such project.

Saying this however, ground gas and contamination is an expansive subject and can be quite different to the waterproofing industry.

DOWNLOAD THE FULL ARTICLE HERE

The Principles of Waterproofing

British Standard 8102:2022 is the ‘Code of practice for protection of below ground structures against water ingress’, and it defines three “Grades” of waterproofing depending on the desired internal environment:

- Grade 1a – Seepage and damp areas from internal and external sources are tolerable, where this does not impact on the proposed use of below ground structure.

- Grade 1b – No seepage. Damp areas from internal and external sources are tolerable.

- Grade 2 – No seepage is acceptable. Damp areas as a result of internal air moisture/condensation are tolerable; measures might be required to manage water vapour/condensation.

- Grade 3 – No water ingress or damp areas is acceptable. Ventilation, dehumidification or air conditioning necessary; appropriate to the intended use.

Seepage is defined as the slow transmission of water through discrete pathways of a structure. Where seepage occurs there is a high risk of the formation of free lime/salt deposits caused by calcium hydroxide being dissolved from the cementitious matrix forming a solid calcium carbonate when exposed to the carbon dioxide within the air.

Dampness is defined as an area which is still wet but with no seepage.

The British Standard also outlines three “Types” of waterproofing system that can be used, either standalone or in combination, in order to achieve these Grades:

- Type A (barrier protection), either internally or externally

- Type B (structurally integral protection)

- Type C (drained protection)

Consideration should be given to combining these Types of waterproofing in any scenario where the assessed risks are deemed too high, or where the consequences of failure are unacceptable.

How Does Waterproofing Best Practice Approach Gas Proofing?

When it comes to considering protection against both water and gas, the first paragraph of Section 4 of the British Standard states that:

“Strategies for dealing with all external sources of groundwater, surface/flood water, soil gases and contaminants should be determined from the very earliest stages of the planning and design processes for any project involving below ground structures.”

Consequently, when required, Newton will always recommend waterproofing products that possess third-party tested gas resistance. In turn, these systems may also be verified by an independent specialist depending on the gasses that are present.

In waterproofing, the safest designs always seek to combine two or more forms of protection, with one of those forms always being a Type C system, supported by the Type A and B products.

The important next step is to be able to assess the level of gas protection that each waterproofing element provides.

Protecting Against Radon

The most important document to consider for radon protection is the BR 211 ‘Radon: Guidance on protective measures for new buildings’.

In previous editions, BR 211 stated that if a basement structure was “tanked” with a product of equal performance to a 1200-gauge DPM then it would provide sufficient protection. As a result, Newton has third-party test results for Radon resistance on some of our external waterproofing membranes.

However, in Section 6.12 of the most recent 2015 edition, BR 211 now recognises that:

“Below-ground waterproofing and radon management are specialist activities that can conflict. It is recommended that dual protection systems are designed and installed by specialists who are suitably qualified in both waterproofing and radon management.”

Newton’s cavity drain membranes are third-party tested for radon resistance, and we developed the patented Newton PAC-500 system for high-risk radon sites. By partnering with gas protection specialists Prestige Air, the PAC-500 system combines Type C waterproofing with a positive air curtain (PAC) ventilation system that controls both water and gas in any below-ground structure, whether it is new or existing, domestic or commercial.

Protecting Against Methane & Carbon Dioxide

British Standard 8485:2015 is the ‘Code of practice for the design of protective measures for methane and carbon dioxide ground gases for new buildings’, and when it comes to basement structures, in Section A4 it states:

“In general terms, a basement constructed of dense, cast in situ concrete appropriately designed to BS EN 1992 to provide integral waterproof protection normally represents the most impermeable of structural forms. Combining this with a waterproof membrane to create a fully tanked basement provides the best basement solution for preventing the ingress of ground gases.”

As with the previous editions of BR 211, “tanking” is being used here as a catch-all term for waterproofing. In this case however, the word indicates what we would call an external or internal Type A waterproofing membrane.

However, as waterproofing designers, we must consider the gas protection capabilities of our entire design, including all three Types of waterproofing and the structure itself.

Assessing the Gas Capabilities of a Waterproofing Design

British Standard 8485:2015 provides all of the tools needed to accurately assess the gas capabilities of our waterproofing designs.

The first step is knowing the Characteristic Situation (CS) value of our site – this will be established during your site investigation and ranges from CS1 (very low risk) to CS6 (such high risk that some sites cannot be built on).

Once this is known, we can use Tables 3, 4, 5, 6 and 7 from the British Standard to:

- Calculate the minimum gas protection score required for our project

- Allocate gas protection points to the different elements of our structure and our waterproofing in order to try and meet the minimum score

For full details on the scoring system and the points that can be allocated to different design elements, please download the full article from this page.

Utilising Waterproofing Products for Gas Proofing

There are several Newton products that have been tested and meet the standards for use as protection against gas below-ground. However, with gas proofing as in waterproofing, the most effective designs combine multiple forms of protection, and always include a Type C cavity drain membrane system.

To begin with, the third-party certified HydroBond 403 Plus GB (gas barrier variant) meets with Section C2 ‘Available Membranes’ of British Standard 8485, and exceeds the performance levels of the 0.4mm polythene sheet which is recommended by the standard for above-ground scenarios (and which is not suitable for below-ground use).

HydroBond 403 Plus GB also has lap tests for methane and carbon dioxide, and it is important that the figures for the tests (along with any other discontinuities such as pile heads or foundations) are taken into account and averaged over the whole basement area.

Designing for Defects

In waterproofing, the legal precedent set by the ‘Outwing vs Weatherald’ high court case states that:

“overlapping self-adhesive membranes cannot be expected to achieve a total or absolute watertight bond capable of resisting penetration by water pressure.”

Therefore, regardless of a products’ laboratory testing, we must expect defects in such membranes and ensure that our design accounts for this. Consequently, best practice in waterproofing is to combine systems, and the safest designs emphasise both a correctly designed reinforced concrete structure and an internal Type C waterproofing system.

Issues of Ventilation

Table 6 of British Standard 8485 outlines how additional gas protection points can be achieved by using external ventilation. However, when we correlate with below ground waterproofing best-practice, there is a clash where we design to account for a full head of groundwater pressure coming to bear against the structure at some point in its design life. Such a scenario would mean that any external ventilation would fill with water.

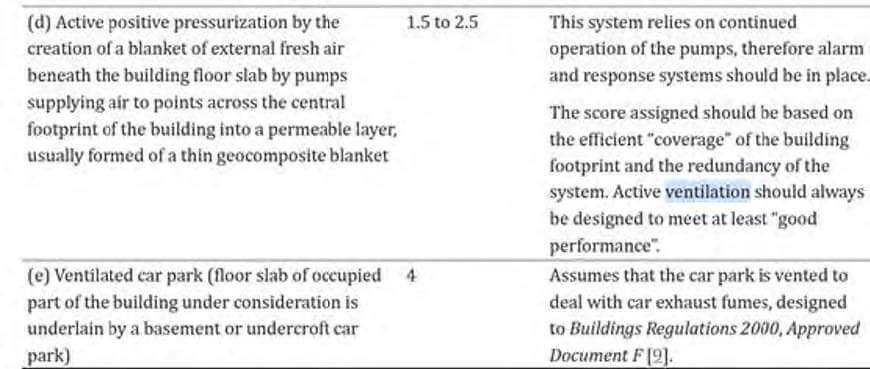

It is possible to ventilate internally though; for example, a below-ground concrete car park with just a Newton Hydrotank Type B waterproofing system can achieve 6.5 gas protection points, a very high score when one considers its waterproofing performance grade. (according to Table 5 and Part (e) of Table 6, as shown below).

In waterproofing terms, Newton always specifies a Type C system where the consequences of failure are unacceptable, and, in our opinion, the gas protection points available for a Grade 3 basement in Table 5 of BS 8485 should not be attributed without the use of Type C waterproofing.

The ‘Positive Air Curtain’ Solution

Despite the problematic statements within BS 8485:2015, generally one would not normally specify a single form of waterproofing, especially in scenarios where there is both water and gas present.

For a Type C system to form an effective gas barrier, all of the laps need to be sealed and the condensation strip removed, which places much greater importance on the internal dehumidification and ventilation systems.

A third-party tested Type C membrane, such as Newton 508R, is also required, which has been tested against methane, carbon dioxide and radon.

However, where the greatest protection is required, the Newton Type C System can be upgraded into a Newton PAC-500 positive air curtain.

The Newton PAC-500 System is a patented, serviceable and high-performance solution that combines Type C basement waterproofing and ground gas mitigation, and can be accepted by the design team to achieve further gas protection points from Table 6 of British Standard 8485.

Summary

Overall, the British Standard recommendations and requirements for gas protection and waterproofing (as outlined by BS 8485:2015 and BS 8102:2022) must be considered in combination.

Whilst the requirements of BS 8485 are perfectly designed for above-ground, there are ways in which these recommendations fall short when viewed in the context of protecting a below-ground structure against both gas and water.

Despite this, for those wishing to protect their below-ground structure, there are multiple options through which they can achieve the required protection, in accordance with both BS 8485 and BS 8102 – whether they plan on using external, gas-tested membranes, a correctly designed concrete structure, an internal PAC-500 positive air curtain, or a combination of methods.

Regardless of the chosen method, it is a necessity that the installation is verified by an independent gas specialist, as outlined by CIRIA 735, ‘Good practice on the testing and verification of protection systems for buildings against hazardous ground gases’.

Fortunately, the gas specialist who wrote the site report is often able to undertake this role, and Newton can also supply a list of verification companies from the British Verification Council who can fulfil this responsibility.

Finally, as well as all of the gas considerations that have been discussed in this paper, it is important not to forget potential contaminants in the ground such as VOCs (volatile organic compounds).

With this in mind, Newton has a third-party testing letter outlining the suitability of Newton 403 HydroBond-GB for resistance to VOCs. And whilst we have not specifically undertaken submersion and vapour testing for the chemicals outlined in the CIRIA 748 document, ‘Guidance on the use of plastic membranes as VOC vapour barriers’, the solutions that have been outlined and discussed in this paper are still suitable.

FAQ

What is gas protection for buildings?

Gas protection is a vital technical measure aimed at averting or managing the infiltration of gas into properties and structures. These systems hold utmost importance in projects developed on land that is subject to continuous ground gas and/or volatile organic compound (VOC) contamination.

DOWNLOAD THE FULL ARTICLE HERE

For more information on this technical article, or to speak to our Technical Team, please call 01732 360 095, email tech@newtonwaterproofing.co.uk or fill out the form below.

Customer Success Stories

Our latest customer reviews from Feefo - the award winning review platform

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.