01732 496 523

The Newton HydroBond System Explained

The British Standard for Waterproofing, BS 8102:2022, defines three ‘Types’ of waterproofing:

- Type A (barrier) – Where a barrier membrane, liquid or sheet, is applied to the structure, either internally or externally.

- Type B (integral) – The structure itself is the waterproofing.

- Type C (drained) – An internally applied drainage system collects and removes water that has managed to pass through the structure or the waterproofing as described above.

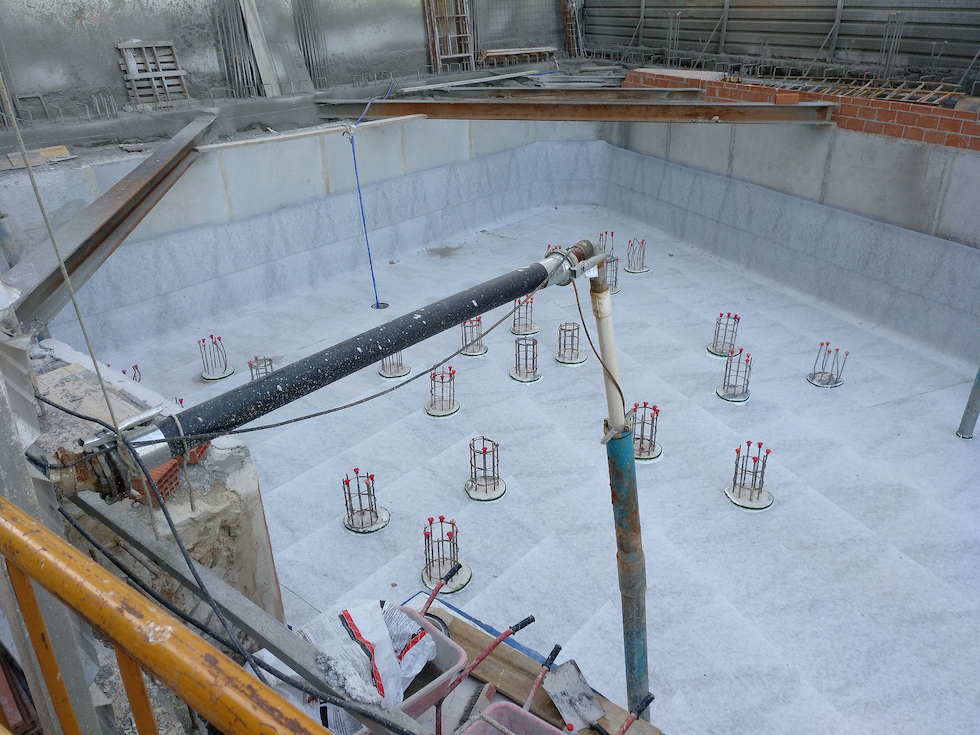

The Newton HydroBond System is a high-performance, Type A waterproofing system designed to be applied to the outside of the structure. The system is either pre-applied below the concrete raft/slab and wall building line, or post-applied where conventional formwork is removed to expose the outside of the basement walls.

The Newton HydroBond System is a high-performance, Type A waterproofing system designed to be applied to the outside of the structure. The system is either pre-applied below the concrete raft/slab and wall building line, or post-applied where conventional formwork is removed to expose the outside of the basement walls.

Once installed and, depending on the type of structure it is applied to, the combination of selected products within the HydroBond System can provide a continuous barrier around the full extent of the structure.

Depending on the products employed, the HydroBond System can provide protection against both groundwater and ground gasses such as radon, methane and carbon dioxide, making it the ideal solution where protection from any or all of these elements is required.

The BS 8102:2022 states in section 8 that membranes should be fully bonded to prevent lateral migration of water from a defect as per Figure 7. This can be tested by manufacturers to BS EN 1928 method A; and that the level of full bond is relevant to depth of use or water pressure

Products within the HydroBond System

Sheet Membranes, pre-applied below raft/slab or to building line, prior to placement of reinforced concrete

- HydroBond 403 – Fully bonded self-healing membrane with reactive polymer hydrophilic core

- HydroBond 403 GB – Fully bonded self-healing membrane with additional aluminium core for optimised radon, methane and carbon dioxide performance

- HydroBond 402 CCS-M – Fully bonded waterproofing membrane, that is pre-applied blinding or fixed to building line prior to the placement of the concrete

Sheet Membranes, post-applied to walls after removal of formwork

- HydroBond SA – Self-adhesive sheet membrane with radon protection

- HydroBond SAGM – Self-adhesive sheet membrane with aluminium core for methane and carbon dioxide resistance

Liquid-Applied Membranes, post-applied to walls after removal of formwork

- HydroBond 2K-Flex – Thick bitumen compound applied in two coats, the first of which is reinforced, that is durable, flexible and provides both waterproofing and radon protection

- HydroBond 109-LM – Radon certified, flexible, bitumen-based paint for both waterproofing and radon protection

HydroBond System Ancillary Products

- HydroBond Tape – Adhesive jointing tape for the three pre-applied membranes

- HydroBond SA Primer LT – Primer for the two self-adhesive membranes

- HydroBond SA Reinforcing Strip – Reinforcement of the standard self-adhesive membrane at changes of direction

- HydroBond SAGM Detail Strip – Reinforcement of the self-adhesive gas membrane at changes of direction

- HydroBond 2K-Flex Primer – Bonding agent that also lowers porosity of concrete and masonry substrates

- HydroBond 2K-Flex Mesh – 160g/m2 reinforcement mesh embedded within the first coat of HydroBond 2K-Flex

- HydroBond 410 GeoDrain – Drainage and protection board that is applied to the waterproofing to protect the walls during the back-filling process

- HydroBond Protection Board – Protection board that is applied to the waterproofing to protect the walls during the back-filling process

The table below confirms which combination of products can be used together depending on the project requirements:

| Pre/applied below raft/slab | Pre-applied to walls | Post-applied to walls | |

| Waterproofing only | HydroBond 403 or HydroBond 402 CCS-M | HydroBond 403 or HydroBond 402 CCS-M | HydroBond 109-LM, HydroBond 2K-Flex and HydroBond SA |

| With radon protection | HydroBond 403 or HydroBond 402 CCS-M | HydroBond 403 GB or HydroBond 402 CCS-M | HydroBond SAGM |

| With methane/carbon dioxide protection | HydroBond 403 GB or HydroBond 402 CCS-M | HydroBond 403 GB or HydroBond 402 CCS-M | HydroBond SAGM combined with HydroBond 109-LM or HydroBond 2K-Flex |

Please note that in some cases, a combination of HydroBond 2K-Flex and HydroBond SA or HydroBond SAGM should be used together, especially where:

- The wall surface is uneven and requires smoothing ready for the application of HydroBond SA or HydroBond SAGM.

- The system is designed to avoid defects outlined in BS 8102:2022 Section 4.3.2.

- The system is intended to eliminate lateral migration as per BS 8102:2022 Section 8, Figure 6.

Design of the Waterproofing System

The waterproofing design should be undertaken by a waterproofing specialist, appointed as part of the design team so that an integrated waterproofing solution is created. The waterproofing specialist should:

- be suitably qualified and experienced commensurate with the type and size of the proposed project;

- be capable of devising solutions that accommodate the various project constraints and needs with an understanding of construction forms and sequencing; and

- provide the design team with information and guidance that assists with and influences the design, installation and future maintenance of the waterproofed structure.

If the RIBA stages are used, a waterproofing specialist should be appointed before the technical design stage at the latest.

A geology and hydrology assessment should be carried out, although the removal or drainage of groundwater should only be considered if it is safe and practical to do so, which in most cases will be where the basement structure is built within sloping ground.

Where there is no slope to allow for successful movement of the groundwater away from the building by gravity, and the ground investigations show a high-water table or an undetermined water table, it should be assumed that the ground could be fully saturated at some point in the future and that a full height of water pressure should be expected.

The waterproofing design should consider how the structure is to be constructed and from which materials, as well as the intended use of the below-ground space and the internal floor and wall finishes. Advice regarding the required ‘Grade’ of waterproofing can be found within the current version of the British Standard:

- Grade 1a – Seepage and damp areas from internal and external sources are tolerable, where this does not impact on the proposed use of below ground structure.

- Grade 1b – No seepage. Damp areas from internal and external sources are tolerable.

- Grade 2 – No seepage is acceptable. Damp areas as a result of internal air moisture/condensation are tolerable; measures might be required to manage water vapour/condensation.

- Grade 3 – No water ingress or damp areas is acceptable. Ventilation, dehumidification or air conditioning necessary; appropriate to the intended use.

Structural Waterproofing – An Overview

Waterproofing Design Specialists are tasked to determine the use of combined protection in various forms where, in a single system:

- the assessed risks are deemed to be high; or

- the consequences of failure to achieve the required internal environment are deemed too high.

With this in mind, the possible combinations of waterproofing are:

- Type A, B & C

- Type A & B

- Type A & C

- Type B & C or

- Type A & A

Where a combination is being considered, systems should have different performance characteristics to mitigate the risk of failure due to a common cause. The compatibility of the different protection types should also be assessed in order to minimise the risks and negate the need for remedial measures

Where multiple forms of waterproofing are deemed to be required and depending on the form of structure to be waterproofed, the Newton HydroBond System can be used in conjunction with the following systems to deliver the required enhanced levels of waterproofing performance:

- Internal Type A – Newton HydroCoat System

- Type B – Newton HydroTank System

- Type C – Newton CDM System

Newton Waterproofing Index (NWI)

The Newton Waterproofing Index is a unique specification tool in the construction industry, providing specifiers and designers with a scoring system in order to accurately assess the level of risk and potential success involved in a waterproofing design.

The Newton Waterproofing Index is a unique specification tool in the construction industry, providing specifiers and designers with a scoring system in order to accurately assess the level of risk and potential success involved in a waterproofing design.

Depending on the many considerations within BS 8102, some of which are highlighted above, the Newton HydroBond System can provide high-performance protection against groundwater and ground gasses, either as a standalone system for the lower grades of waterproofing performance or in conjunction with other Newton Waterproofing Systems where enhanced protection is required.

Having maintained our Professional Indemnity (PI) Insurance for waterproofing designs for over 20 years, Newton is also able to support specifiers with our bespoke waterproofing design service, backed by our insurers and our PI policy.

Our team of dedicated technical staff are all trained Certificated Surveyors in Structural Waterproofing (CSSW) and able to assist you with your project, from design to quality assurance visits and on-site training via our specialist site support team.

Contact Newton Waterproofing on 01732 360 095, or email tech@newtonwaterproofing.co.uk to speak to a member of our team.

Customer Success Stories

Our latest customer reviews from Feefo - the award winning review platform

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.